What is PVD?

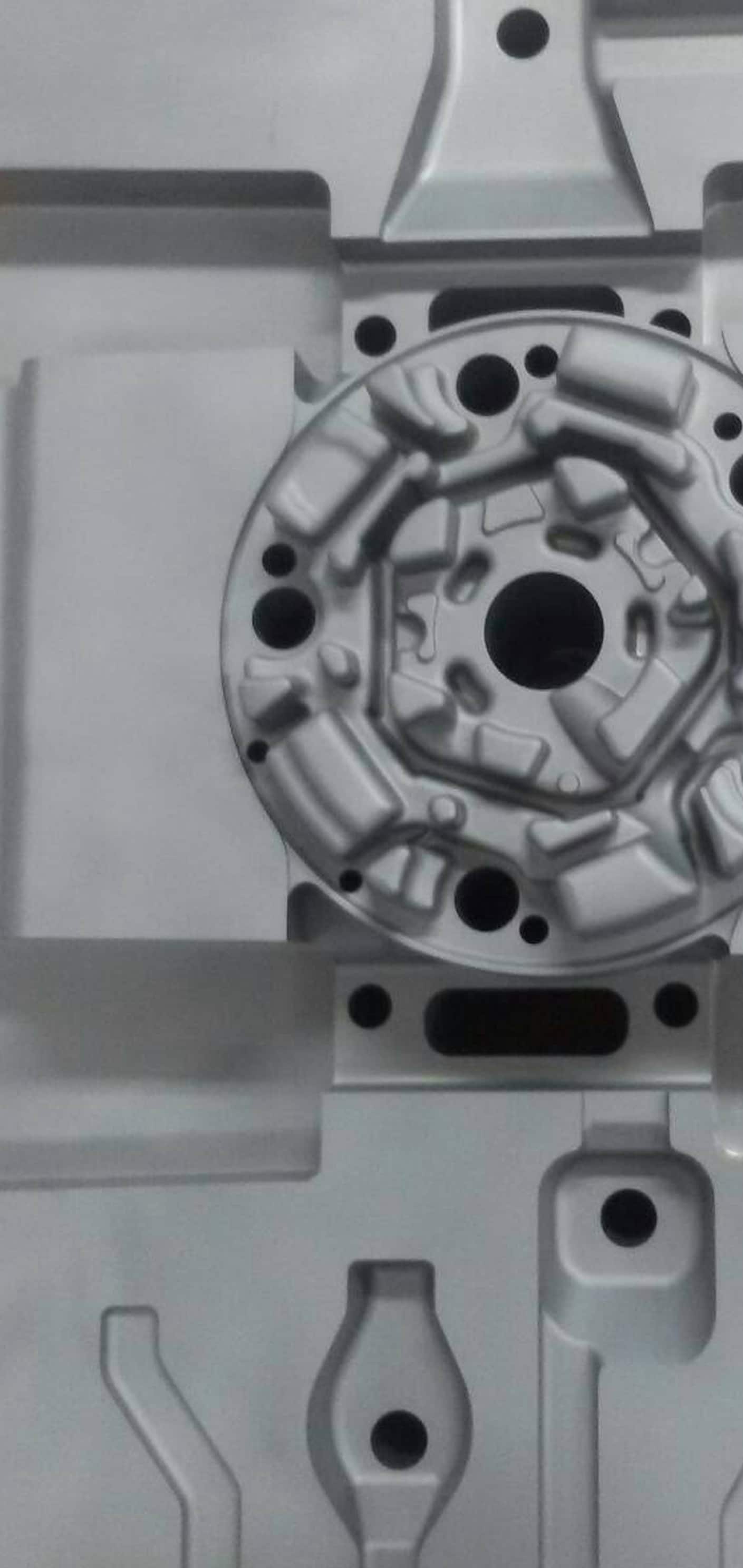

Physical Vapor Deposition (PVD) is widely used technique for the superior features than general tools such as increase tool life, Lubricataion, Wear resistance, etc. of tools. PVD has been used a lot at the industrial scale especially automotive part and mold makerฺ

Basic on coating.

A coating is a hard thin film (micrometer unit), adhesion layer of chemical compound that us applied to a workpiece.

- Increased tool life / wear resistance.

With high hardness and low coefficient of friction will help the surface material to bear less load. Which will also reduce the wear of the material.

- Increase production efficiency

The coating can increase the cutting speed, reduce maintenance time.

- reduce cost

Reduce wear and increase service life Will help save on buying or creating new tools

The following table show you a comparison of the different technicial parameter of the six coatings.

| TiNa-A | GolA | GiaN | TiNa-C | TiNa-AT | CroM | |

|---|---|---|---|---|---|---|

| Composition | TiAlN/TiN | TiN | AlCrN | TiCN | TiAlN/TiN | CrN |

| Hardness (HV) | 3700 | 2700 | 3700 | 3000 | 4000 | 2250 |

| Standard Thickness (μm) | 2.0-4.0 | 2.5-4.0 | 3.0-5.0 | 3.0-6.0 | 6.0-16.0 | 6.0-18.0 |

| Maximum Operate Temp. (℃) | 900 | 600 | 1,037 | 400 | 900 | 600 |

| Visual Color |

Additional coating information

|

|