TiNa Service Technology Co.,Ltd.

CEO GROUP

Mr. Chanchai Chaodee

Mr. Uthai Sriwilai

We providing PVD coating services for tooling of valve parts with the Plasmadiam system. The coating that we have regular batches; + TINA-A (TiAlN/TiN-ML) + TINA-C (TiCN) + TINA-GolA (TiN) + TINA-GiaN (AlCrN) + TINA-CroM (CrN) + TINA-AT (TiAlN/TiN-Extra Thick) ………………….. We also provide training and consulting on PVD principles service. Including maintenance of machinery in the PVD process.

Our Process

– Incoming Inspection

Inspect workpieces before being put into the process to ensure that the work pieces are the most complete.

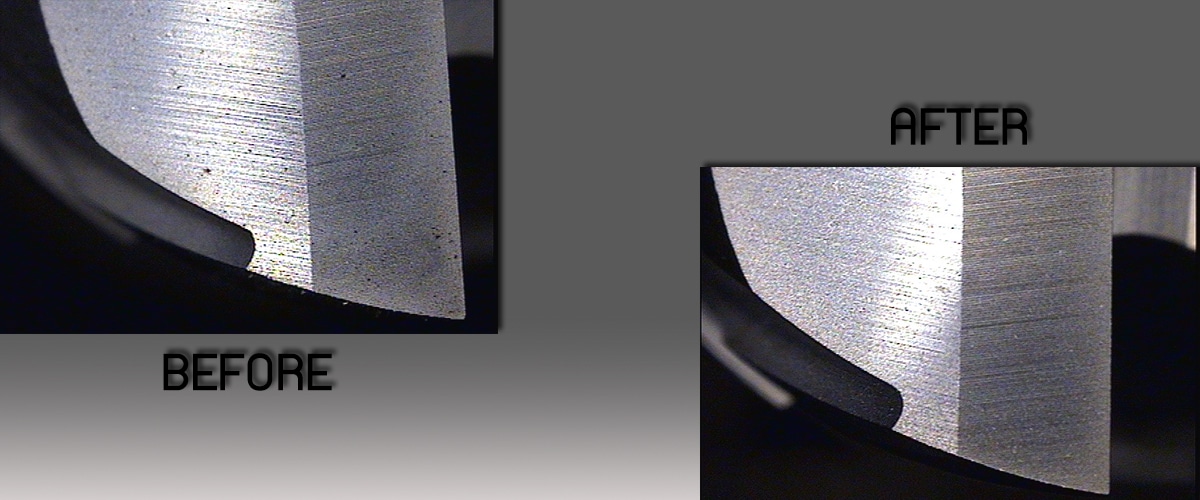

– Pre-Treatment

Our first process is to cleaning the workpice. Which may have other processes such as + striping + GB + MB + Lapping To get the most ready to be coatied work piece.

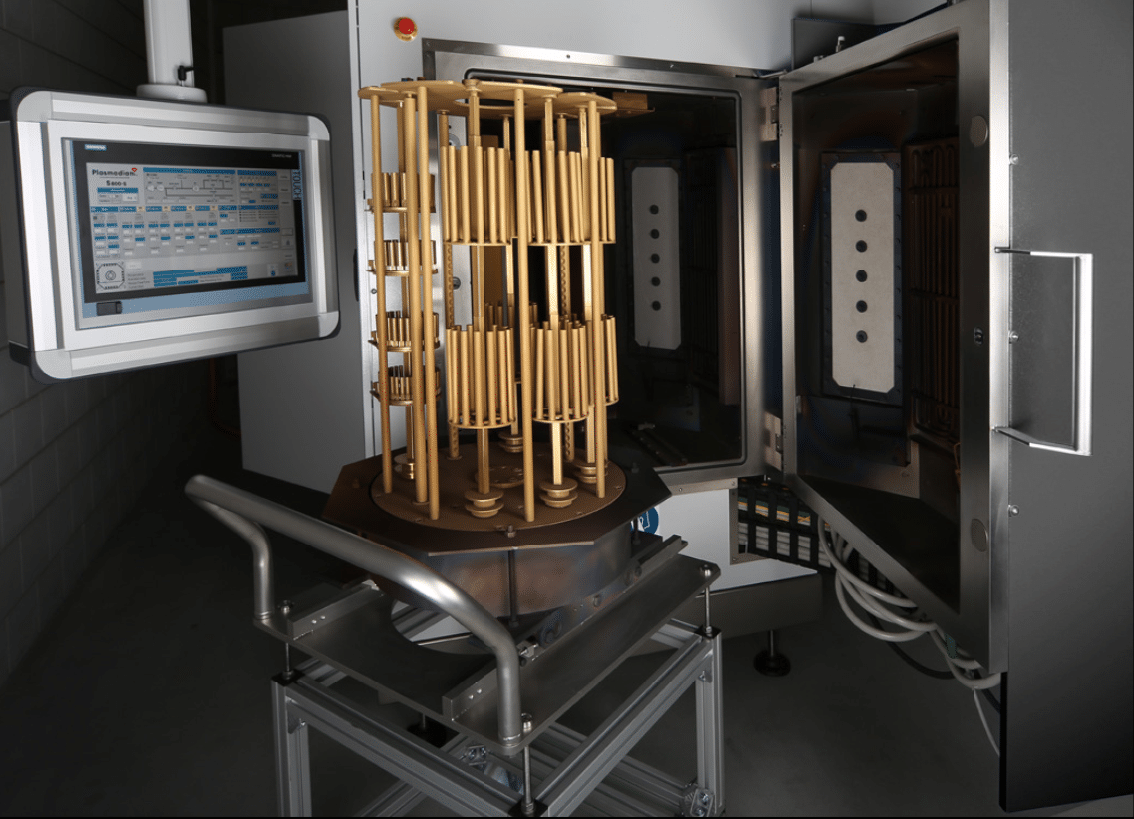

– Fixturing & Coating

Designing workpieces that are suitable for the coating process to meet the needs of the most customers.

– Post-Treatment

In order to get rid the *droplet we have a post-treatment process for the workpices surface to be smooth.

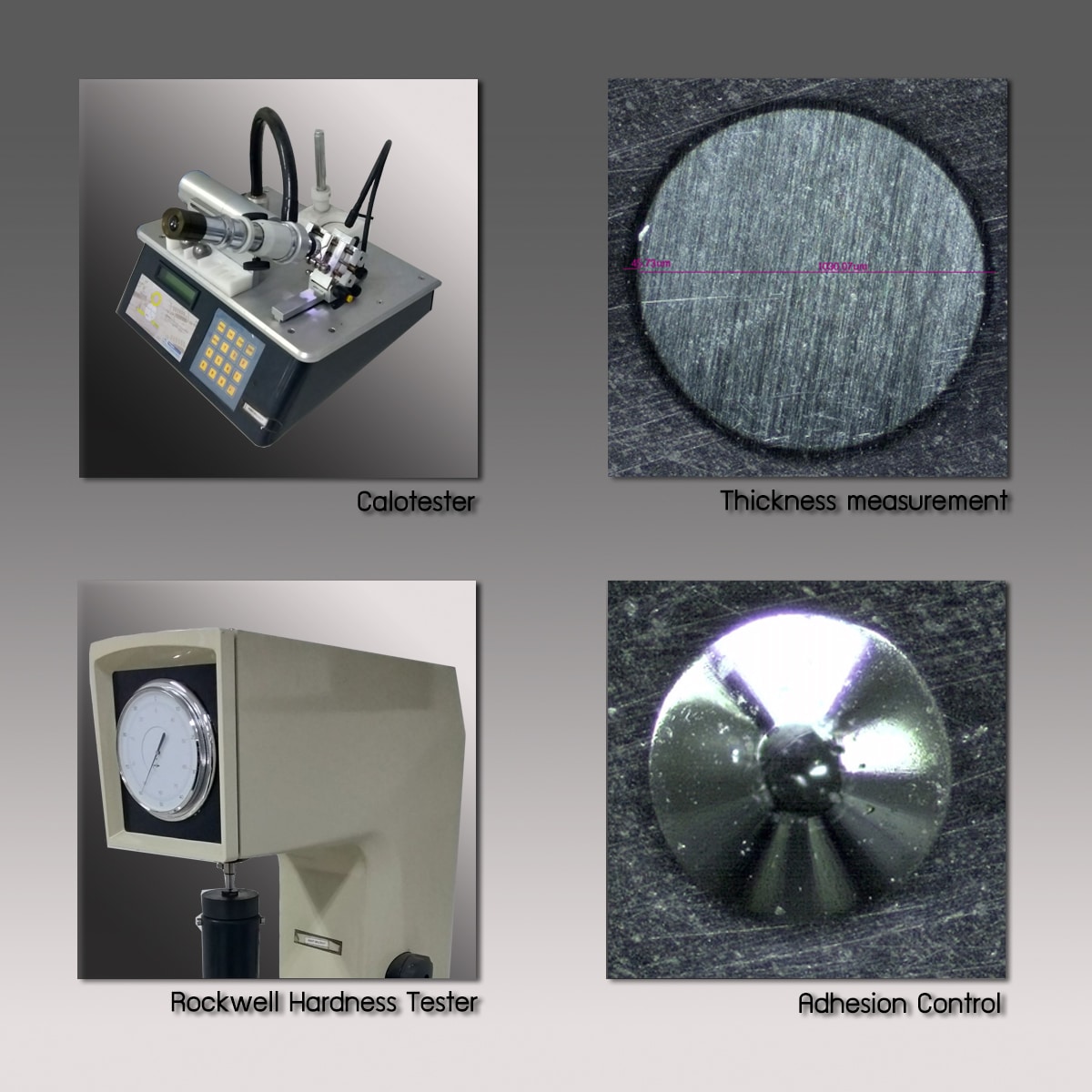

– Coating Quality Check

In addition to inspection the workpiece. We also come to inspect specimens for reference, thickness and adhesion.

*Droplet in PVD process is defect to make the tool surface unsmooth.

Our Location

– Office

88/147 Moo.1, Mheang, Muang, Chonburi 20130 Thailand.

– Factory

98 Moo.14, Hin dat, Dan Khuntod, Nakorn Ratchasima 30210 Thailand.

Taxpayer Identification Number : 0205556009382